We know that sewn product manufacturers like yourself, feel like you are operating in the dark and trying to make decisions on old data days after you needed to make a change.

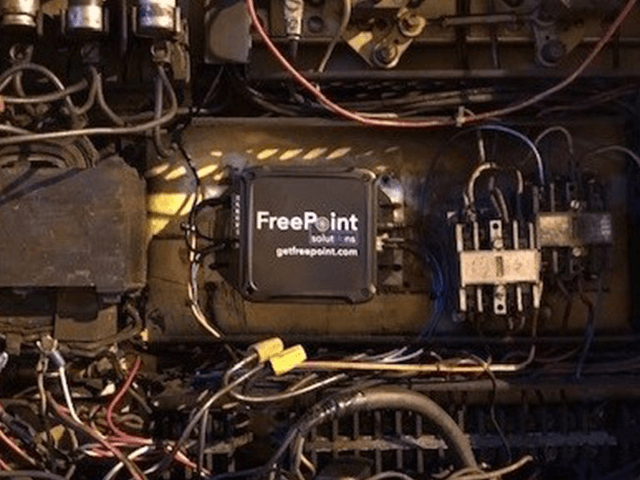

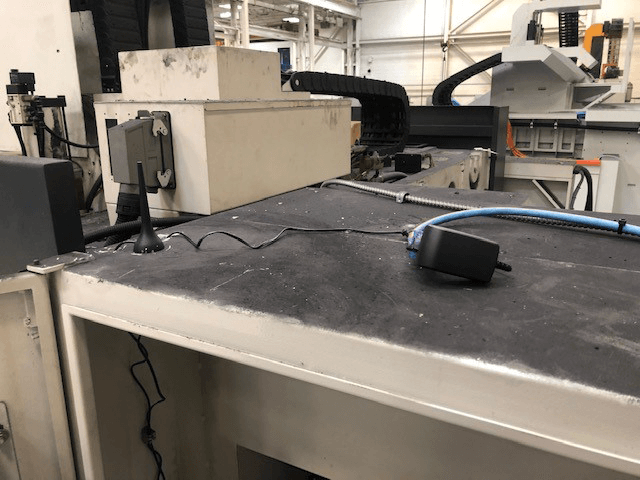

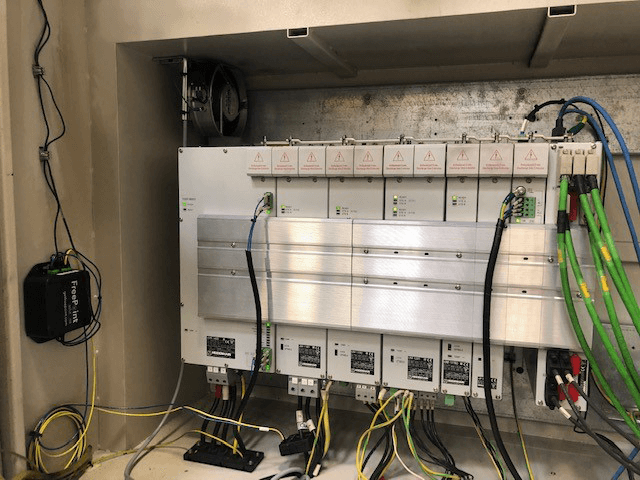

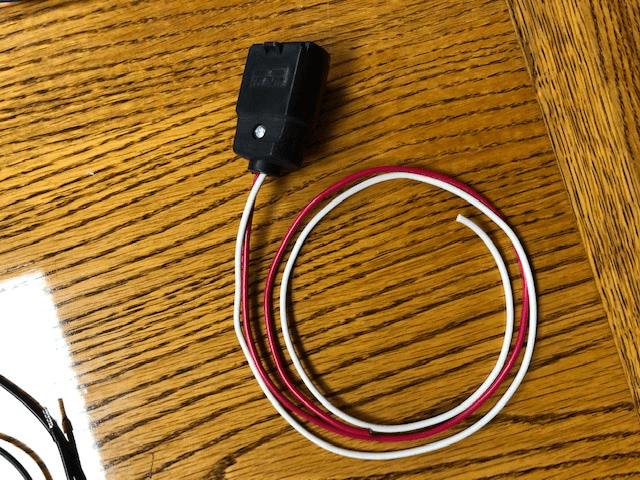

It was important for us to choose the best partner for machine monitoring. A partner that could provide a solution for any machine, any age, and help you connect, monitor, and engage your machines and employees.

Get a feel for what the FreePoint solution offers you and then book your demo with us today.

freepoint technologies

FreePoint was established on the simple notion that every process, in every factory, can and should be monitored and measured. They work with all levels of manufacturing to create smart factory connections that facilitate detailed data collection and analysis, ensuring that your operational decisions are based on up-to-date and relevant metrics. They strive to help connect you to your machines and with your people.

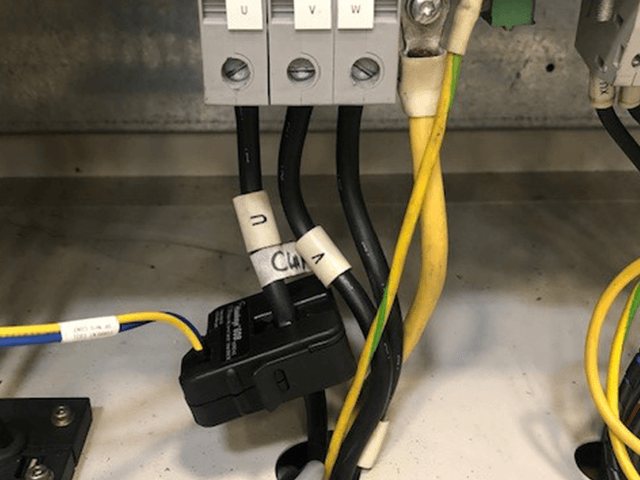

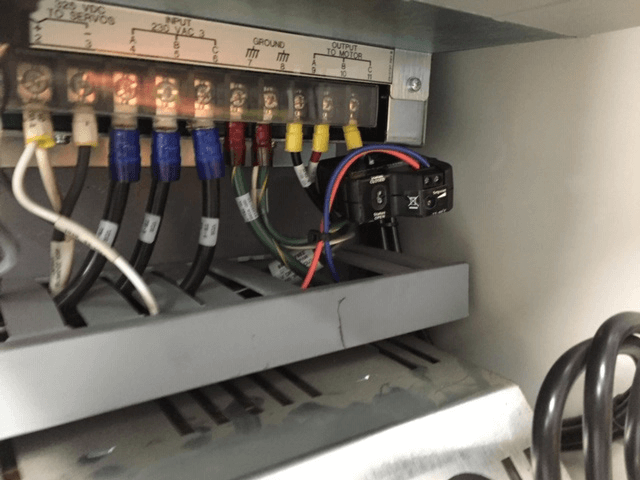

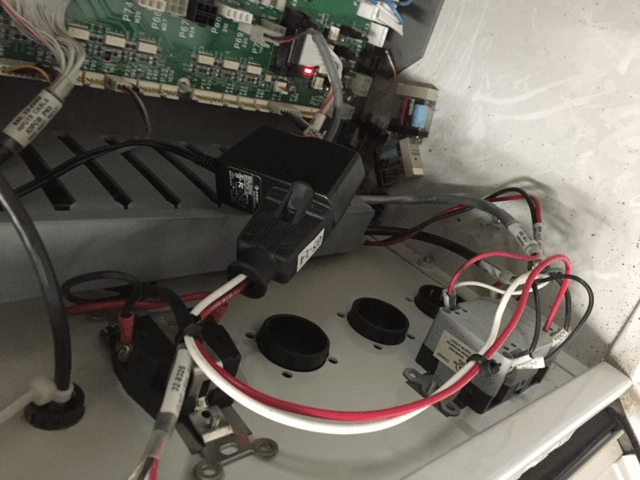

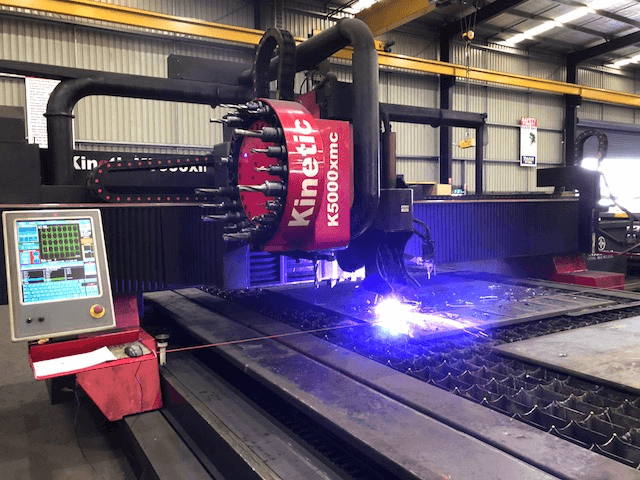

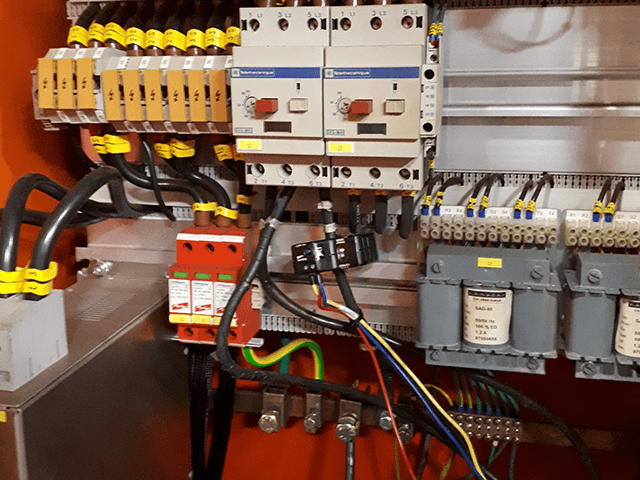

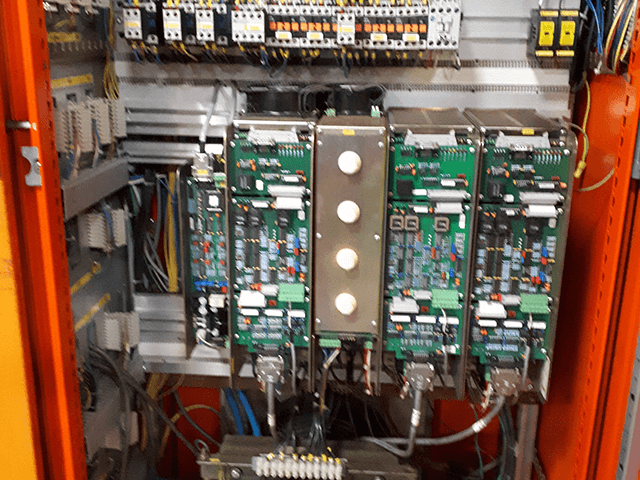

The fact is that many older machines continue to deliver good quality output, and due to the nature of the work they do, there is little advantage that newer technology could bring. (You can’t bend steel, or forge, or draw copper any faster than physics will allow).

Also, most machines in these industries are very large and are often installed when the plant is built. Replacing them just doesn’t make sense. However, connecting them to the same data collection platform for uptime, downtime, scheduling, preventative and predictive maintenance does.

Old machines are still in use for a reason – because they are critical to the production of the product. It just makes sense to connect them too.

And with FreePoint, you can.

See What FreePoint Customers Say…

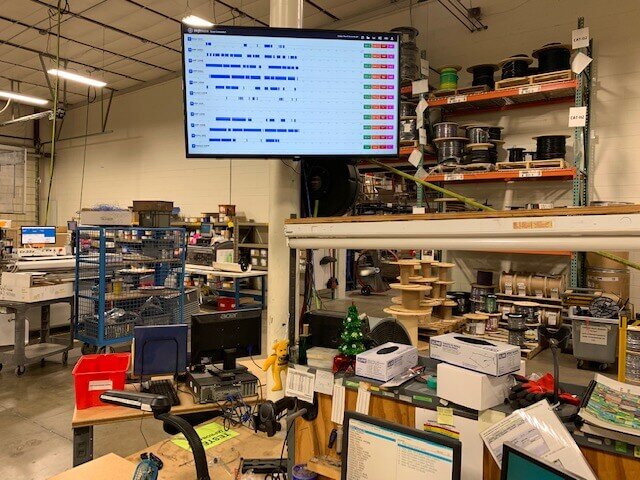

FreePoint Solution in Action

How The FreePoint Solution Works

Let’s book your demo today so you can see FreePoint in action.